Overview

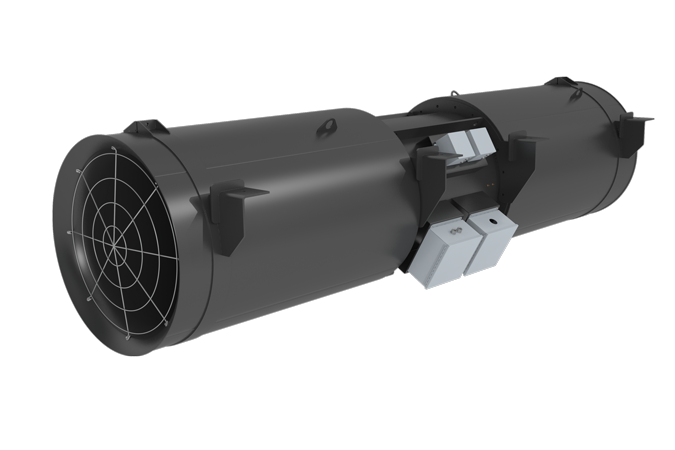

The need for tunnel ventilation is critical for the life and safety of any person utilizing the metro, rail or road tunnels throughout the world. Typically the equipment is used for smoke extraction or control for the time it takes people to evacuate the tunnel under emergency conditions. They are also utilized to control exhaust fumes and to provide standard ventilation when required. Primary standards for tunnel ventilation include NFPA 130 – Standard for Fixed Guideway Transit and Passenger Rail Systems and NFPA 502 – Standard for Road Tunnels, Bridges and Other Limited Access Highways.

There are three basic types of control that can be applied: portal to portal, shaft to shaft, and portal to shaft. These are used independently or in conjunction with each other. Fans utilized are axial and jet fans, both reversible and unidirectional, as well as centrifugal.

Whatever the installation requires, Clarage can provide the solution.

Performance Overview

- IMPELLER SIZES: Up to 315″ (8,000 mm)

- AIRFLOW: Up to 1,500,000 CFM (2,548,500 m3/hr)

- STATIC PRESSURE: Up to 36″ w.g. (8,950 pa)

- TEMPERATURE RANGE: Up to 752°F (400°C)

- Motor Sizes: Up to 1,500 HP (1,118 KW)

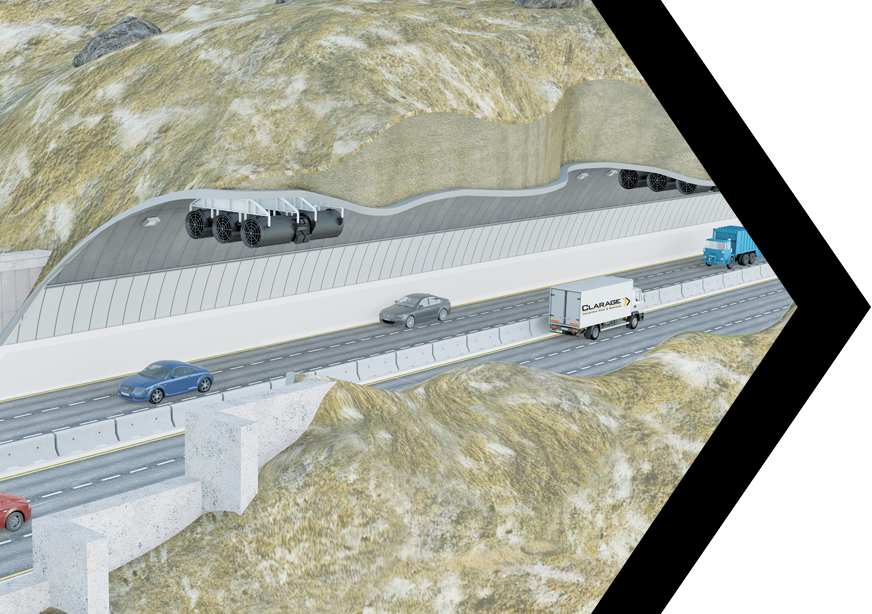

Portal to Portal

The concept of portal to portal is typically completed with the use of jet fans. These specially designed units are inclusive of an attenuator on either end and direct the air from one portal to the other by inducing the air to move. These units are rated on the thrust that they can impart to the surrounding air in the tunnel. This air movement is sustained by the thrust being energized repeatedly down the length of the tunnel by various banks of jet fans. The principal objective is to have the air contaminated with smoke move in the opposite direction of the evacuation route. This will allow the people to exit with fresh air blowing in their face.

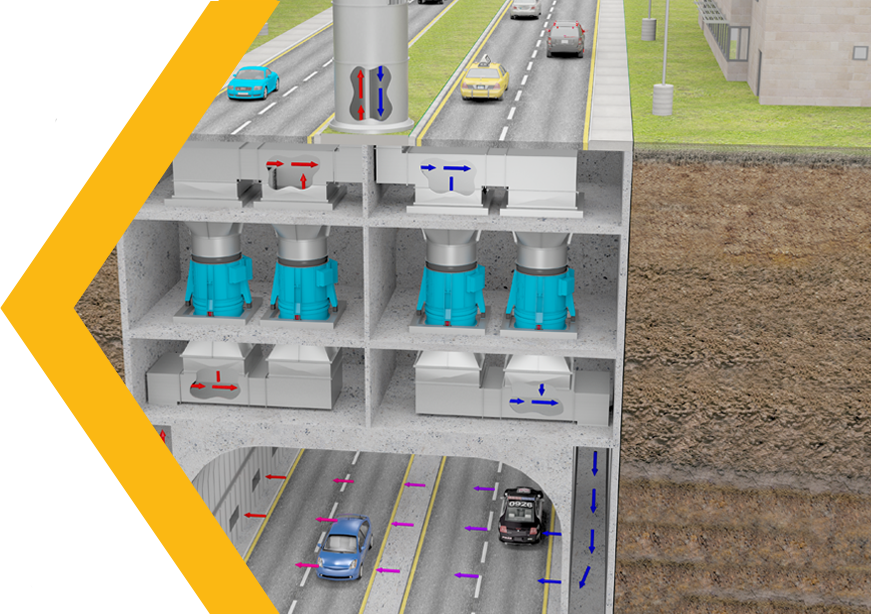

Shaft to Shaft

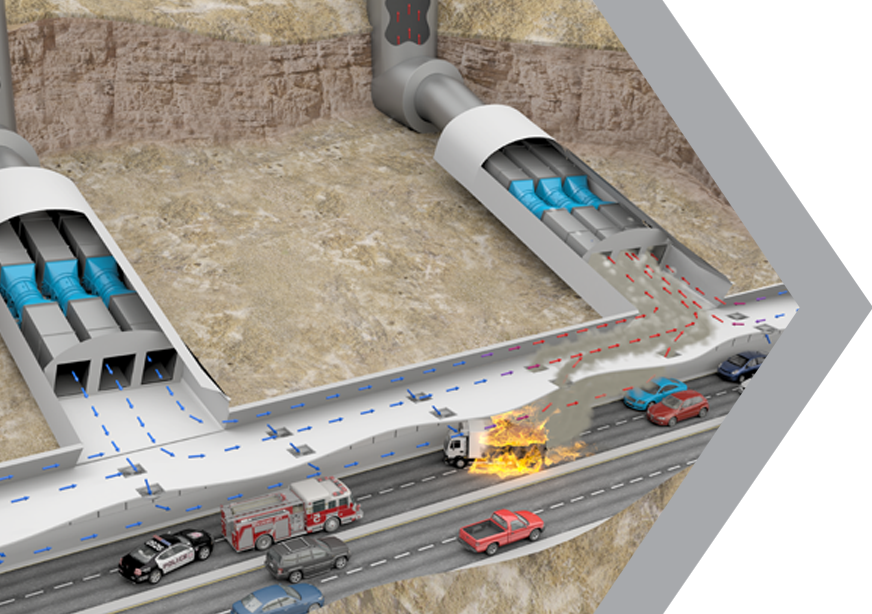

The concept of shaft to shaft is a push pull system. The air is forced in the required direction by either a single unit or a station of fans on either side of the fire event. It is standard for the air to be injected from one station and extracted at the other. Thus the equipment utilized for this type of arrangement must be reversible. The principal objective is to have the smoke-contaminated air move in the opposite direction of the evacuation route. This will allow the people to exit with fresh air blowing in their face.

Portal to Shaft

The concept of portal to shaft is a combination of portal to portal to shaft to shaft. The air is forced into the tunnel and then extracted out of the portal via jet fans. Or, depending on the location of the fire event, the airflow may be reversed. Hence, the equipment utilized for this type of arrangement must be reversible. The principal objective is to have the air contaminated with smoke move in the opposite direction of the evacuation route. This will allow the people to exit with fresh air blowing in their face.