Industries Served

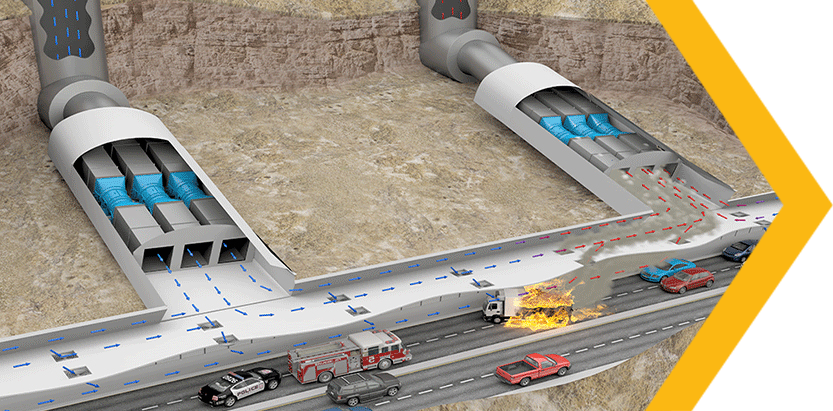

Tunnel Ventilation

For many years tunnel ventilation system design engineers have prepared specifications for fans and associated equipment that included the requirements of The National Fire Protection Association (NFPA) Standard 130, which is the standard for Fixed Guideway Transit and Passenger Rail Systems. The standard requires that equipment must be capable of operating at elevated temperatures for extended periods of time during a fire emergency. Unfortunately, the fan industry did not have test facilities capable of demonstrating compliance with these specification requirements. We recognized that claiming compliance to a design requirement is far short of demonstrating compliance. That is why Clarage built one of the largest and most versatile high temperature test facilities in the industry. Not only is our facility capable of testing all components of a fire life safety ventilation system (fans, dampers and sound attenuators) at the specified temperature, we can simulate actual fire emergency conditions. The facility is designed to model the “thermal shock” that will likely occur during an emergency. A by-pass loop is utilized to preheat air to the specified temperature and then, through a series of dampers, the preheated air is introduced into the test chamber to replicate actual fire conditions. In our view, there is no better method to demonstrate complete compliance to the standards.