Engineering Services

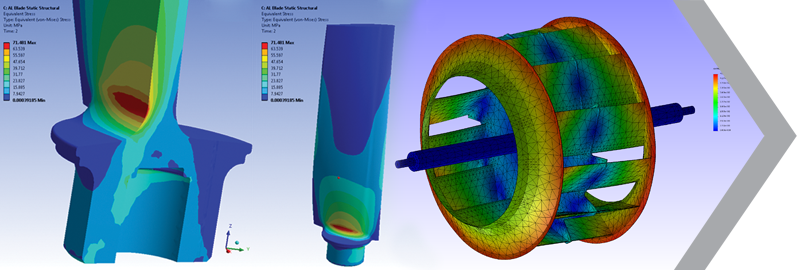

- FINITE ELEMENT ANALYSIS

- NON-DESTRUCTIVE EVALUATION

(NDE) – ULTRASONIC, RADIOGRAPHY, DIE PENETRATION, MAGNETIC - TORSIONAL ANALYSIS

- TRANSIENT TORSIONAL ANALYSIS

- BEARING ANALYSIS

- COMPUTATIONAL FLUID DYNAMICS (CFD)

- SYSTEM MODEL EVALUATION

- ROTOR DYNAMIC ANALYSIS

IN-HOUSE TESTING CAPABILITIES

- AMCA 204 BALANCE & VIBRATION TESTING

- AMCA 210 PERFORMANCE TESTING

- AMCA 250 JET FAN THRUST TESTING

- AMCA 300 SOUND TESTING

- ROTOR IMPACT (BUMP) & OVERSPEED TESTING

- HIGH TEMPERATURE/ SURVIVABILITY TESTING

- MECHANICAL RUN TESTING

- NARROW BAND SOUND & VIBRATION TESTING AND ANALYSIS

- STRAIN GAUGE TESTING

- OPERATIONAL MODAL TESTING

Performance & Mechanical Run Tests

Test Lab – AMCA 210 Chamber

Clarage can provide accurate and repeatable airflow, pressure and power data for fans of all types by performing an airflow measurement test per AMCA standards 210 and 260 using one of three chambers that are located in our test lab. Two of the chambers can accommodate airflow rates up to 65,000 cubic feet per minute and static pressures up to 10 inches of water while the third high pressure chamber can handle airflow rates up to 10,000 cubic feet per minute and static pressures up to 80 inches of water.

MANUFACTURING PLANT – AMCA 210 DUCT TESTING

When a fan exceeds the size limitations of our chambers, large scale duct testing can be conducted at one of our manufacturing plants. Clarage can provide accurate and repeatable results by performing airflow measurement testing per AMCA standard 210 for fans of virtually any size, airflow rate, static pressure and horsepower. This method of testing is very space consuming and requires a very long duct section to be attached to the fan.

MANUFACTURING PLANT – MODIFIED AMCA 203 GUIDELINES

Another option for determining the airflow performance of fans that are too large for our chambers is to perform an airflow measurement test using guidelines from AMCA publication 203 at one of our manufacturing plants. For this particular test, fans are installed with ductwork on the outlet and either a bell or duct on the inlet. This results in accurate and repeatable testing and generally requires less space than an AMCA 210 duct test.

High Temperature Testing

The test fan is installed in a closed loop system that recirculates the heated air through the fan. This ensures that the mechanical design of the fan is able to stand up to the hot environment. Clarage’s customers can be certain that when the fan is installed in a high temperature application, it is ready to do the job.

Finite Element Analysis (FEA)

Clarage products are engineered and optimized through a series of analyses and validation including Finite Element Analysis (FEA). These tools are used to verify the structural integrity of our products under various loading conditions, analyze the natural frequencies, as well as analyze torsional natural frequencies. To better serve our customers, we can offer these services upon request.